Stirling Engine

Starting with raw materials and preliminary design constraints…

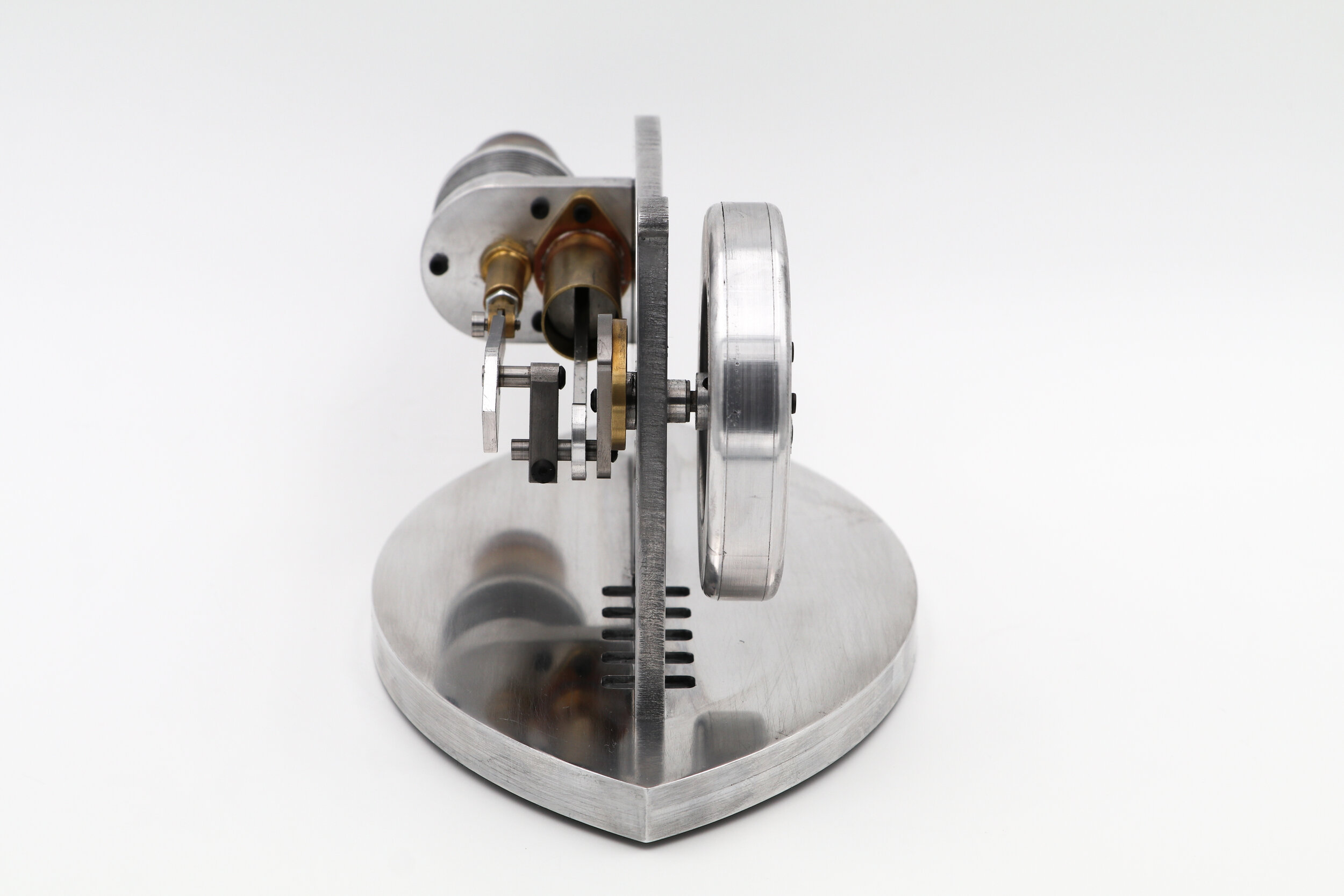

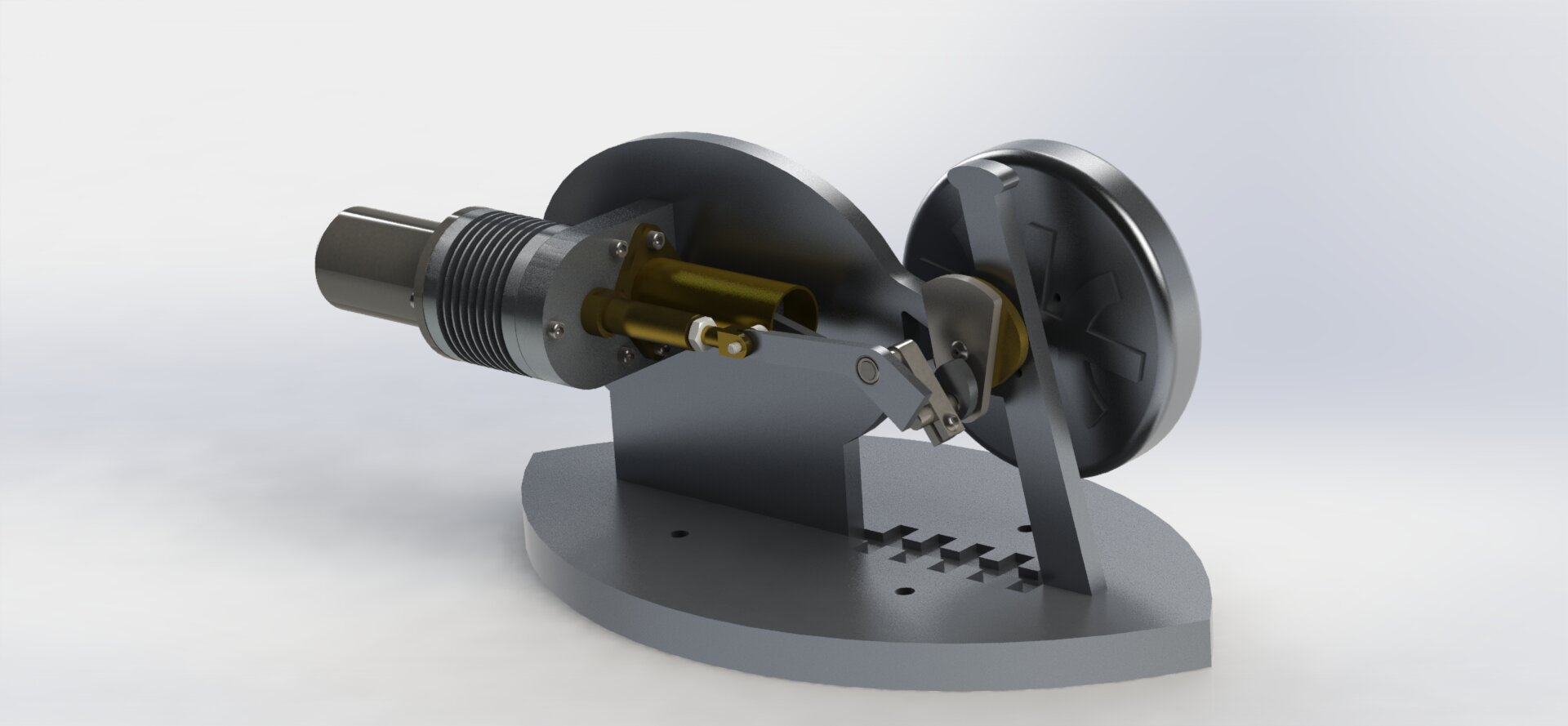

I designed, machined, assembled, and tested my own Gamma-type Stirling heat engine. I combined practicality with creativity in creating sports-themed SolidWorks models for over half of the 60+ parts, including flywheel, base, bedplate, and various connecting rods. I then assembled the parts into multiple layers of assemblies, resulting in a single virtual heat engine demonstrating the necessary motion capabilities. I also drafted up various engineering drawings for machine shop staff approval, and additionally performed a GD&T tolerance stackup to avoid catastrophic failure within feasible machining constraints.

Throughout the entire semester…

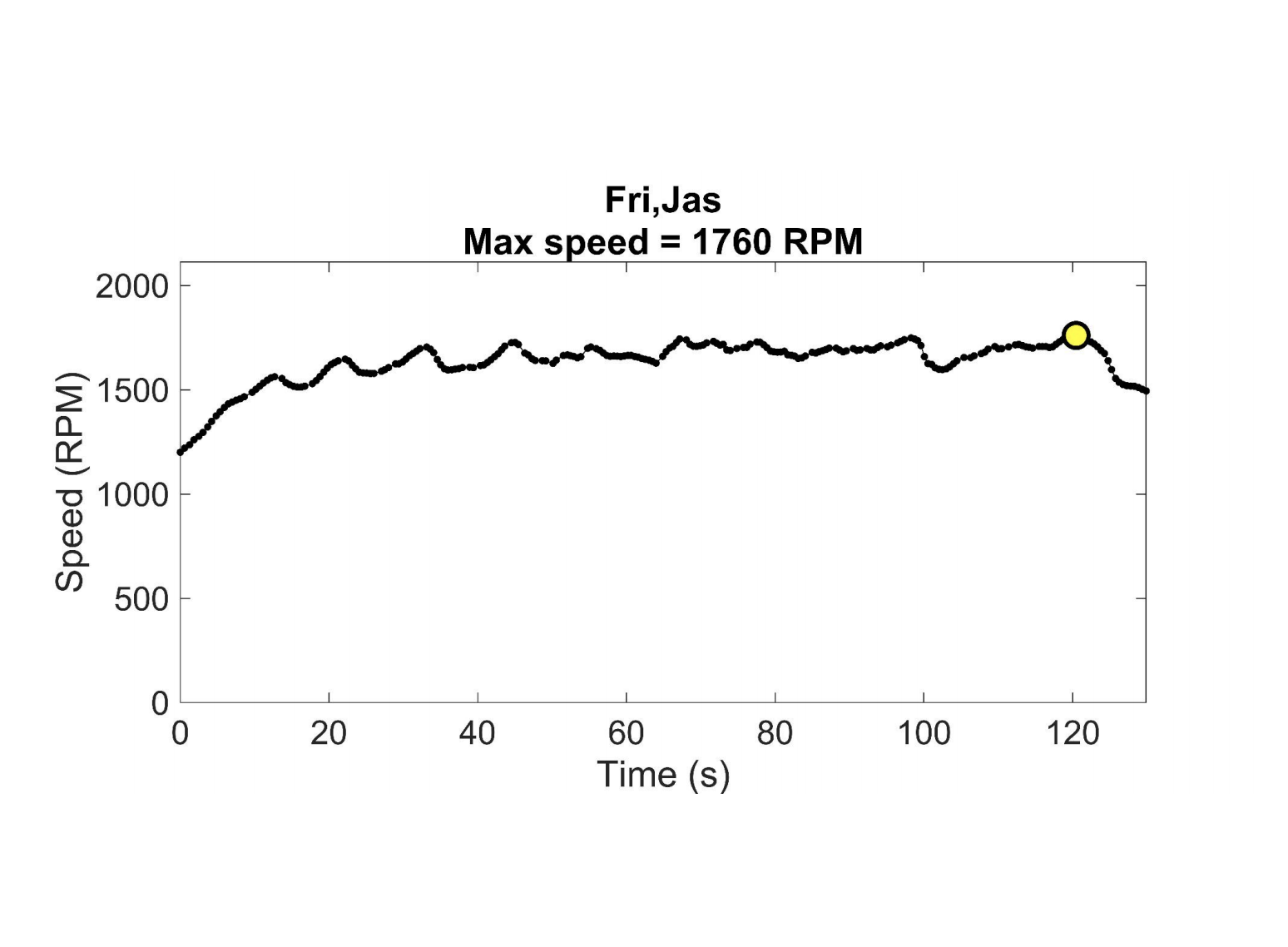

I used my part models and drawings to machine each individual part, using tools such as CNC mill, lathe, band saw, drill bits, and reamer bits. Certain parts required extra manufacturing efforts, for example machining a custom fixture, and/or generating G-code to automate the milling process via ProtoTRAK software. I then polished and sanded each finished component before assembling and testing them as subassemblies, then finally a single finished product. On the final testing day, the engine ran via initiation by initial kinetic energy and heat of a blow torch, and subsequently spun at 1760 RPM.